If you are in the market for a metal roofing system, you’ll find a wide range of material options available, including aluminum, copper, zinc, galvanized, stainless steel, and Galvalume®.

Galvalume, a steel-based product, is the most commonly used metal in architectural metal roofing and is suitable for almost every building application.

What is your level of knowledge about Galvalume? Are you familiar with the key benefits and drawbacks of this metal roofing material?

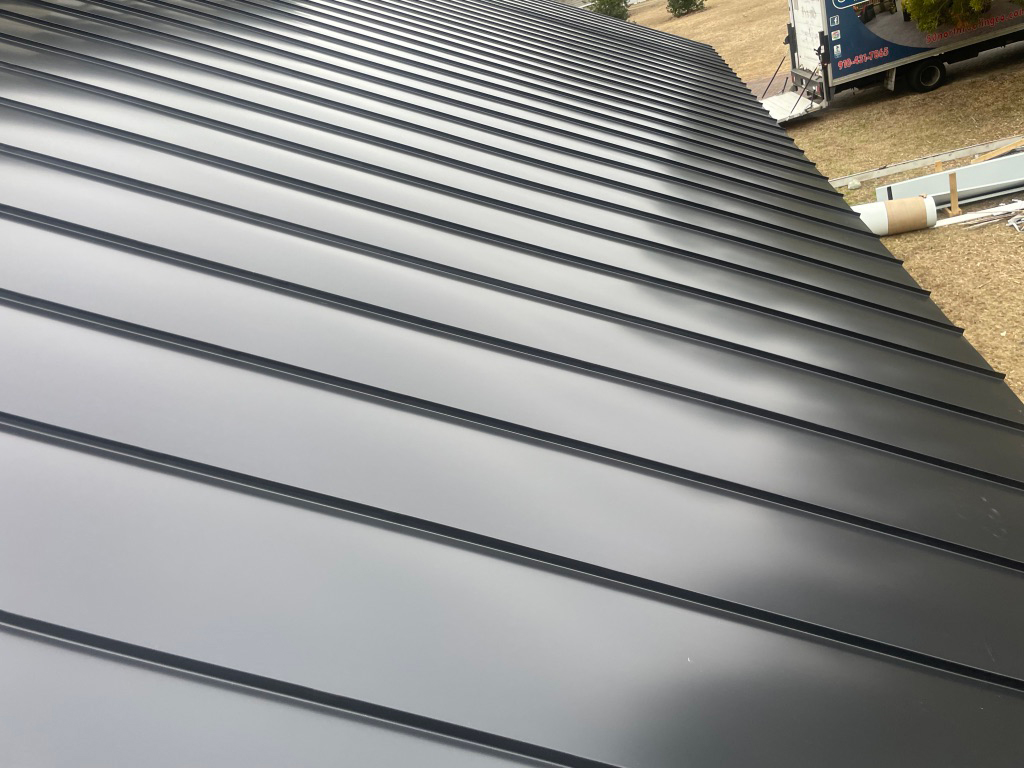

At 50 North Roofing, our main products include the galvalume standing seam metal roofing system, which is commonly used in the architecturally-driven metal roof and wall industry. It’s crucial for you to make an informed decision as a buyer, so let’s discuss the specific details of this material and determine if it’s the right choice for your project.

In the following article, we will discuss the following topics related to Galvalume: What is Galvalume, Uses for Galvalume, Advantages of Galvalume, and Disadvantages of Galvalume.

What Is Galvalume®?

In the early 1970s, Bethlehem Steel revolutionized the construction industry by introducing the Galvalume coating. Prior to Galvalume, most metal roofing was made of galvanized steel. However, due to the impressive durability and corrosion resistance of Galvalume, over 90% of the metal roofing industry shifted from galvanized substrates to Galvalume substrates in the mid to late 1990s.

Galvalume is a roofing material that includes a combination of steel, aluminum, and zinc. The manufacturing process involves applying aluminum and zinc alloys to a cold-rolled carbon steel base sheet until it reaches a coating of 55% aluminum, 43.4% zinc, and 1.6% silicone.

This process enables one material to combine the best characteristics of multiple metals, making it a popular choice for metal roofing.

Galvalume is sometimes known by its coating weights, which are referred to as AZ-50 and AZ-55. Let me explain what these terms signify.

The typical coating weight for painted sheet and coil products is AZ-50, which equals 0.50 ounces per square foot of the aluminum-zinc alloy coating applied to both sides of the substrate. For a slightly heavier coating, AZ-55 equals 0.55 ounces per square foot of the aluminum-zinc alloy coating applied to both sides of the substrate.

The standard coating weight for bare or unpainted sheet and coil products, often referred to as acrylic-coated Galvalume or Galvalume Plus, is AZ-55. These products have a slightly heavier coating weight and include a light acrylic coating to protect the Galvalume coating during manufacturing.

Over time, the acrylic coating will wear off with exposure. While not painted, it’s important to handle these products with care to avoid scuffing or perforating the coating.

Uses for Galvalume® Metal Roofs & Walls

In general, Galvalume is appropriate for use as a roof, wall, trim, accent, and more in a wide range of building applications, even in some of the most extreme environments such as non-coastal hurricane zones, areas with high levels of rain or snowfall, high-temperature regions, and more.

Some common uses for Galvalume include:

Various types of buildings and structures, including hospitals, schools, stores, government buildings, single-family homes, multi-family homes, condominiums, warehouses, factories, barns, and more are all part of our architectural, structural, and industrial projects.

Galvalume is not recommended for use in certain situations due to the potential for the aluminum-zinc coating to break down prematurely, leading to a quicker system failure.

Here are a couple of circumstances where Galvalume should not be used:

Galvalume is generally not recommended for use on buildings where animals are housed or held due to the potential for degradation of the metal from ammonia gas produced by animal manure. However, in modern chicken houses with proper ventilation, Galvalume may be used with a vapor barrier between the chicken area and the roof.

It’s important to check with the manufacturer before using Galvalume on an animal confinement building, as its suitability can depend on the specific design and use.

In coastal environments, it’s important to consider the impact of saltwater on building materials. Galvalume coating may not hold up well in these conditions, leading to premature damage to roofs and walls.

To combat this, it’s recommended to use an engineered aluminum roof system, as aluminum is much more resistant to corrosion and rusting from saltwater.

It is advisable to consult with the manufacturer to determine the recommended course of action if your project is situated in one of these environments or if you are uncertain whether your location is corrosive to Galvalume.

Advantages & Benefits of Galvalume® Metal Roofing

Warrantied Product

Galvalume has a number of selling points, including a 25-year warranty on the substrate, also known as a perforation warranty. Additionally, Galvalume systems often come with paint warranties, providing further protection and peace of mind for your roof or wall system. However, it’s important to note that substrate or paint warranties are not available for Galvalume products within 1,500 feet of a coast.

Additionally, commercial property owners have the option to purchase a weathertight warranty for their Galvalume roofing structure, guaranteeing proper installation and adherence to strict installation details.

Corrosion Resistance & Self-Healing Properties

Galvalume’s self-healing properties effectively prevent red rusting at any cut or exposed edges. While most steel-based products may experience some edge creep from exposed steel when the coil is cut, the minimal creep will eventually stop with Galvalume. It’s important to note that edge creep can also be minimized by hemming the panels and touching up any exposed edges with paint pens.

Furthermore, the self-healing properties of Galvalume systems reduce the likelihood of roof failure in the field.

Easy to Handle & Install

Galvalume offers the benefit of being more durable and forgiving compared to other metals used in roofing, such as copper and zinc. This means that installers do not need to be as concerned about leaving fingerprints or deep scratches on panels. Additionally, Galvalume does not have strict ventilation or air gap requirements like some other metals, making it a more convenient option for roofing projects.

Additionally, Galvalume is a commonly used metal roofing material with minimal special requirements, making installation details fairly standard across the board.

Installers find Galvalume easy to handle, rollform, cut, and work with, despite its tough material.

Longevity

According to research, Galvalume roofing has the potential to remain intact for over 50 years in favorable conditions with minimal corrosion. This durability makes Galvalume a favorable option for homeowners and property owners seeking a longer-lasting roofing solution compared to traditional asphalt shingles, which typically need replacement every 10-15 years.

Economical & Competitively Priced

Galvalume is generally considered to be a cost-effective option for roofing materials, with pricing typically ranging from $5.00 to $15.00 per square foot, depending on factors such as thickness, color, and quality of the panels. It’s important to note that steel prices are currently fluctuating, so the cost of Galvalume can vary significantly.

Disadvantages & Cons of Galvalume®

Oil Canning

Oil canning is a common occurrence in light-gauge, cold-formed metal products, particularly those with large flat areas. It appears as waviness or distortion in the metal panels, but fortunately, it is purely a visual issue and does not impact the strength or performance of the system. This phenomenon can occur with any type of metal roof or wall, including Galvalume.

There are several methods that can be used to minimize the appearance of oil canning. These include purchasing a thicker sheet or coil product, buying trustworthy brands, rollforming panels with striations or bead stiffeners, hiring an experienced contractor, and ensuring there are no roof decking issues. These practices can help reduce the risk of oil canning and improve the overall appearance of the metal panels.

Interactions with Other Materials

When different metals are combined on a metal roof system, it can cause interactions that may lead to premature degradation, discoloration, and ultimately, the potential failure of the entire system.

Galvalume is most effective when it is not in contact with copper, lead, bricks, treated lumber, iron, and concrete. If Galvalume comes into contact with any of these materials and is then exposed to an electrolyte such as water, it can result in galvanic corrosion of the metal.

Unpainted Galvalume Can Scuff Easier

Contractors should be mindful that installing non-painted Galvalume can result in scuffing off the acrylic coating in high-traffic areas. Once the coating is scuffed, the only solution is to replace the scuffed panels. Leaving scuffed unpainted Galvalume on the roof may cause the roof to become splotchy as the scuffed or exposed parts age and weather quicker.

For the best results when installing unpainted Galvalume, it is recommended to limit foot traffic on newly installed panels, be mindful of ladder placement, and avoid pivoting or pressing shoes/boots down too hard on the installed panels.

Final Thoughts on Galvalume® Metal Roofing

Galvalume is a highly recommended choice for numerous metal roofing projects; however, it is crucial to understand the appropriate times for its installation and when it should be avoided.

Let’s review what we’ve discussed: Galvalume is a durable material designed to withstand the test of time in the appropriate conditions. It has self-healing properties that prevent red rust at exposed edges. Galvalume is easy to work with, versatile, and doesn’t require complex installation.

There are various warranty options for Galvalume, including paint, substrate, and weathertight. Please note that weathertight warranties are only applicable to commercial use. It’s important to avoid using Galvalume in coastal areas or on structures for animal enclosures.

Please feel free to reach out to one of our experienced metal roofing specialists today with any questions you may have about Galvalume or other types of metal roofing materials. We are committed to helping customers and potential buyers make well-informed decisions about the best metal material for their roofing projects, no matter if you are a contractor, architect, property owner, or beyond.