What is Oil Canning on Metal Roofing? A Comprehensive Guide

When it comes to metal roofing, one of the most talked-about concerns is oil canning. This phenomenon, often misunderstood, can impact the appearance of your metal roof. In this guide, we’ll explore what oil canning is, its common causes, and various methods to minimize it. Our goal is to provide you with a thorough understanding of oil canning so you can make informed decisions about your roofing needs.

Understanding Oil Canning

What is Oil Canning?

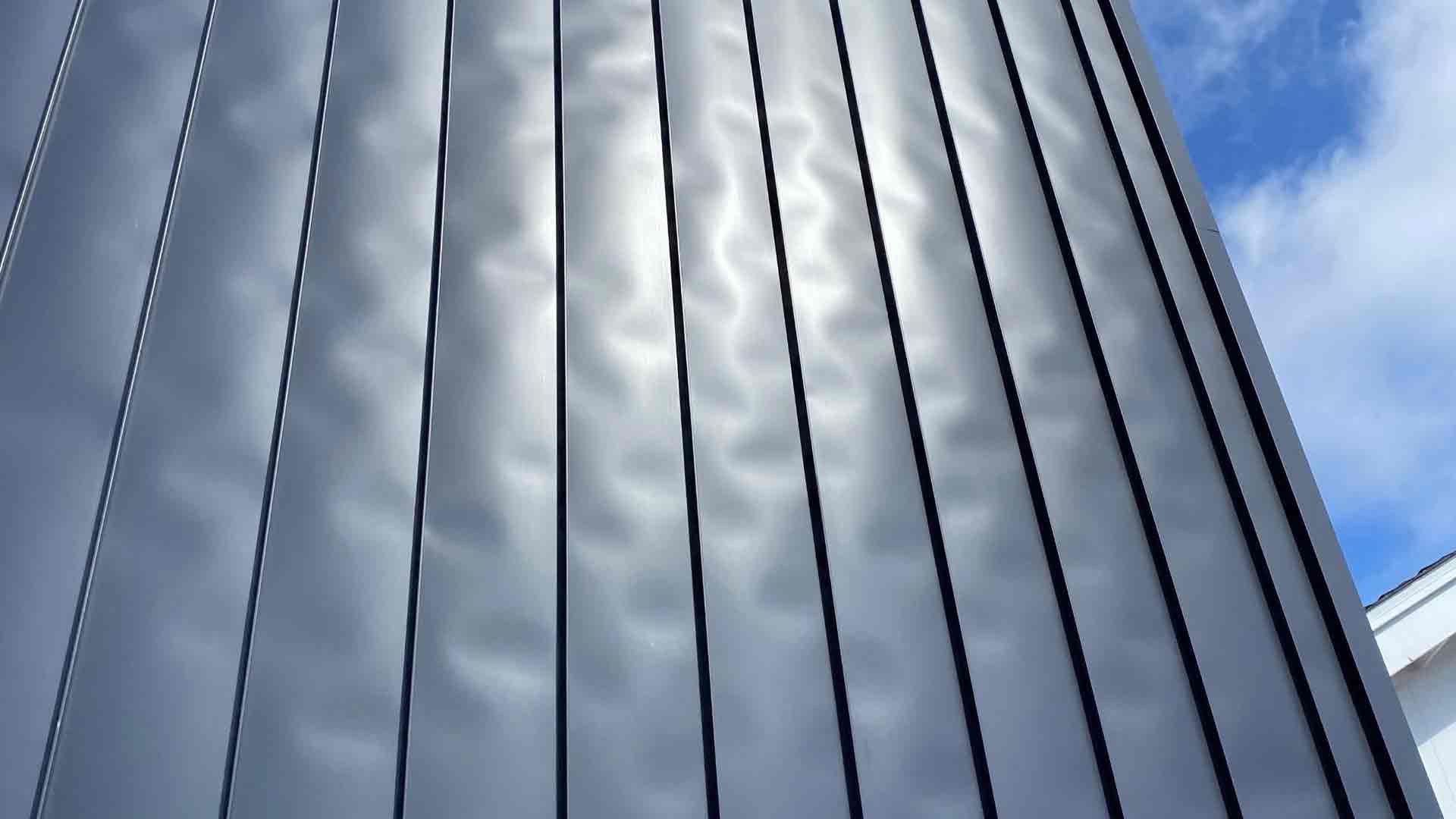

Oil canning refers to the visible waviness or buckling in the flat areas of metal roofing and siding panels. These distortions are typically more noticeable in reflective light and can affect the aesthetic appeal of the roof. While oil canning doesn’t usually affect the structural integrity or performance of the roof, it can be a significant cosmetic concern for homeowners and architects.

Why Does Oil Canning Matter?

While oil canning is primarily a visual issue for metal roofs in North Carolina, it matters for several reasons:

- Aesthetic Concerns: A wavy appearance can detract from the sleek, modern look that metal roofing is known for.

- Perceived Quality: Oil canning can be perceived as a sign of poor quality or improper installation, even though it’s a common issue.

- Customer Satisfaction: Homeowners and building owners may feel dissatisfied with the appearance of their new roof if oil canning is prominent.

Common Causes of Oil Canning

Oil canning can result from a variety of factors. Understanding these causes can help in preventing or minimizing the issue.

1. Material Stress and Manufacturing Processes

Overview:

- Metal roofing panels are often subject to stress during the manufacturing process, including rolling-forming, and cutting.

- Residual Stress: Stress can be induced in the metal during the roll-forming process, leading to oil canning.

- Improper Roll-Forming: Incorrect roll-forming techniques can cause uneven distribution of stress, resulting in visible distortions.

- Cutting Methods: Laser cutting or shearing can introduce stress at the edges of the panels, exacerbating oil canning.

2. Installation Issues

Overview:

- The way metal panels are installed plays a significant role in whether oil canning occurs.

- Over-tightening Fasteners: Fasteners that are too tight can restrict the natural expansion and contraction of the metal, causing buckling.

- Improper Panel Alignment: Misaligned panels can create uneven stress distribution, leading to oil canning.

- Incorrect Substrate: An uneven or improperly prepared substrate can contribute to the appearance of oil canning.

3. Thermal Expansion and Contraction

Overview:

- Metal naturally expands and contracts with temperature changes. This thermal movement can cause stress in the panels.

- Temperature Fluctuations: Significant changes in temperature can lead to expansion and contraction cycles that create stress.

- Panel Size and Shape: Larger panels or those with large flat areas are more susceptible to oil canning due to increased surface area for thermal movement.

4. Structural Movement

Overview:

- The building structure itself can move over time, influencing the performance of the metal roof.

- Building Settling: As buildings settle, the resulting movement can cause stress in the metal panels.

- Wind Load: Strong winds can create pressure that causes panels to flex and buckle.

- Seismic Activity: In regions prone to earthquakes, structural shifts can lead to oil canning in metal roofs.

Different Ways to Minimize Oil Canning

While oil canning cannot be entirely eliminated, several strategies can help minimize its appearance. Here are some effective methods:

1. Choosing the Right Materials

Overview:

- The type of metal and its thickness can influence the likelihood of oil canning.

- Thicker Panels: Thicker metal panels are less prone to oil canning because they are more rigid.

- Higher Quality Metals: Using high-quality metals with consistent grain structure can reduce the risk of oil canning.

- Stress-Relieved Metals: Metals that have been stress-relieved during manufacturing are less likely to exhibit oil canning.

2. Proper Installation Techniques

Overview:

- Careful installation is crucial to minimizing oil canning.

- Use Adequate Fasteners: Avoid over-tightening fasteners and ensure they are properly spaced to allow for natural movement.

- Align Panels Correctly: Ensure panels are aligned properly and that seams are straight to distribute stress evenly.

- Flat Substrate: Install panels on a flat, even substrate to prevent stress points that can cause oil canning.

3. Design Considerations

Overview:

- Design elements can play a significant role in reducing the visibility of oil canning.

- Smaller Panels: Using smaller panels or breaking up large flat areas with ribs or striations can minimize oil canning.

- Texture and Patterns: Adding textures or patterns to the panels can disguise minor waviness and reduce the appearance of oil canning.

- Color Choices: Lighter colors and matte finishes can make oil canning less noticeable compared to dark or glossy finishes.

4. Thermal Management

Overview:

- Managing the thermal movement of metal panels can help prevent oil canning.

- Proper Ventilation: Ensure proper ventilation under the roof to reduce temperature fluctuations.

- Expansion Joints: Use expansion joints in large panels to accommodate thermal movement without causing stress.

- Reflective Coatings: Applying reflective coatings can reduce heat absorption and minimize thermal expansion.

5. Routine Maintenance

Overview:

- Regular maintenance can help identify and address issues that might lead to oil canning.

- Inspection: Regularly inspect the roof for signs of stress or damage that could lead to oil canning.

- Fastener Checks: Check fasteners for tightness and integrity to ensure they are not causing undue stress on the panels.

- Professional Assessment: Have a professional roofer assess the roof periodically to identify and address potential issues early.

- To learn more about this topic, also Read: standing seam or exposed fastener metal roofing system

Frequently Asked Questions About Oil Canning

Can Oil Canning Be Completely Eliminated?

No, oil canning cannot be completely eliminated, but it can be minimized through careful material selection, proper installation techniques, and thoughtful design considerations.

Does Oil Canning Affect the Performance of a Metal Roof?

Oil canning is primarily a cosmetic issue and does not typically affect the structural integrity or performance of the metal roof.

How Can I Tell If My Roof Is Susceptible to Oil Canning?

Large, flat panels and roofs in areas with significant temperature fluctuations are more susceptible to oil canning. Consulting with a roofing professional can help determine the risk for your specific situation.

What Should I Do If I Notice Oil Canning on My Roof?

If you notice oil canning, consult with a professional roofer to assess the extent and explore potential remedies. In many cases, it may be a cosmetic issue that does not require immediate action.

Is Oil Canning Covered by Roofing Warranties?

Oil canning is often considered a natural occurrence in metal roofing and may not be covered by warranties. It’s important to review the warranty details with your roofing manufacturer or contractor.

Conclusion

Oil canning is a common concern in metal roofing, but with the right knowledge and approach, its impact can be minimized. Understanding the causes of oil canning and implementing strategies to reduce its appearance can help you achieve a beautiful, durable metal roof.

There are several ways to prevent oil canning, including selecting the appropriate materials like aluminum or heavier gauge metal, utilizing proper installation techniques, incorporating design elements, and maintaining your roof.

If you’re considering a metal roof or already have one and are concerned about oil canning, contact a professional roofer for expert advice and solutions tailored to your needs. With careful planning and attention to detail, you can enjoy the many benefits of metal roofing without the worry of oil canning.